Modern sensor systems power everything from smart cities to industrial automation, yet hidden biases and coverage gaps often undermine their reliability and accuracy.

🔍 The Hidden Challenge in Sensor Networks

Sensor technology has revolutionized how we collect and analyze data across countless industries. From environmental monitoring stations tracking air quality to sophisticated manufacturing equipment measuring production metrics, sensors form the backbone of our data-driven world. However, beneath the surface of these technological marvels lies a critical challenge that many organizations overlook: sensor bias and coverage gaps.

These invisible problems can significantly impact decision-making processes, lead to incorrect conclusions, and ultimately compromise the performance of entire systems. Understanding how to identify, analyze, and mitigate these issues is essential for anyone working with sensor data, whether in IoT deployments, industrial settings, or research environments.

Understanding Sensor Bias: More Than Just Numbers

Sensor bias refers to systematic errors that cause readings to deviate consistently from true values. Unlike random errors that average out over time, bias persists and can skew data in predictable directions. This phenomenon affects everything from temperature sensors in climate research to pressure transducers in manufacturing plants.

Types of Sensor Bias You Need to Know

Calibration drift represents one of the most common forms of sensor bias. Over time, physical components degrade, environmental factors take their toll, and sensors gradually lose their initial accuracy. A temperature sensor that once provided readings accurate to within 0.1 degrees might drift to 0.5 degrees or more without proper maintenance.

Environmental bias occurs when external conditions influence sensor readings in ways designers didn’t anticipate. Humidity affecting electronic components, electromagnetic interference corrupting signals, or thermal expansion altering mechanical properties all contribute to this type of bias. These factors create systematic errors that vary with environmental conditions.

Installation bias emerges from improper sensor placement or mounting. A temperature sensor positioned too close to a heat source, an air quality monitor sheltered from prevailing winds, or a pressure transducer installed at an angle all introduce consistent measurement errors. The sensor itself might be perfectly calibrated, yet the data remains fundamentally flawed.

🎯 Detecting Coverage Gaps: Finding What’s Missing

Coverage gaps represent blind spots in sensor networks where data collection is insufficient, inconsistent, or entirely absent. These gaps create dangerous assumptions and incomplete pictures of the systems being monitored. Identifying them requires systematic analysis and careful planning.

Spatial Coverage Challenges

Physical space often contains more variation than sensor networks capture. In a large warehouse, a few temperature sensors might miss hot spots or cold zones. Environmental monitoring systems with sparse sensor placement fail to detect localized pollution events. Manufacturing facilities may have adequate sensor coverage for primary processes but overlook critical auxiliary systems.

The cost-benefit tension drives many coverage decisions. Organizations must balance comprehensive monitoring against budget constraints, leading to strategic compromises. However, these compromises sometimes create critical blind spots that only become apparent when problems arise in unmonitored areas.

Temporal Coverage Issues

Time introduces another dimension of coverage gaps. Sensors with long sampling intervals miss transient events. Data logging systems that pause during maintenance windows create temporal blind spots. Battery-powered sensors that enter sleep modes sacrifice temporal resolution for longevity.

Event-driven phenomena pose particular challenges. A chemical leak lasting only minutes, a brief power surge, or a momentary equipment malfunction might occur between sampling intervals, leaving no trace in the data. These temporal gaps can hide critical information about system behavior and failure modes.

🛠️ Analytical Techniques for Uncovering Problems

Systematic analysis reveals sensor biases and coverage gaps that casual observation misses. Multiple complementary approaches provide the most comprehensive assessment of sensor system performance.

Statistical Analysis Methods

Comparing sensor readings against known references establishes baseline accuracy. Ground truth data from calibrated laboratory instruments, manual measurements, or alternative monitoring systems provide benchmarks for identifying systematic errors. Statistical tests quantify the magnitude and consistency of deviations.

Cross-sensor validation exploits redundancy in sensor networks. When multiple sensors monitor similar phenomena, their readings should correlate strongly. Persistent discrepancies between nearby sensors indicate bias in one or more units. Time-series analysis reveals gradual drift that might otherwise go unnoticed.

Distribution analysis examines the statistical properties of sensor data. Expected Gaussian distributions that appear skewed might indicate bias. Missing data patterns reveal temporal coverage gaps. Spatial interpolation techniques highlight areas where sensor density proves insufficient for accurate monitoring.

Visualization Strategies That Reveal Truth

Heat maps transform spatial sensor data into intuitive visual representations. Color-coded displays immediately highlight areas with dense coverage versus regions where interpolation spans large distances. These visualizations make coverage gaps obvious even to non-technical stakeholders.

Time-series plots with confidence intervals expose both bias and temporal gaps. Systematic offsets appear as consistent separation from expected values. Missing data manifests as gaps in the timeline. Overlaying data from multiple sensors reveals inconsistencies that suggest calibration problems.

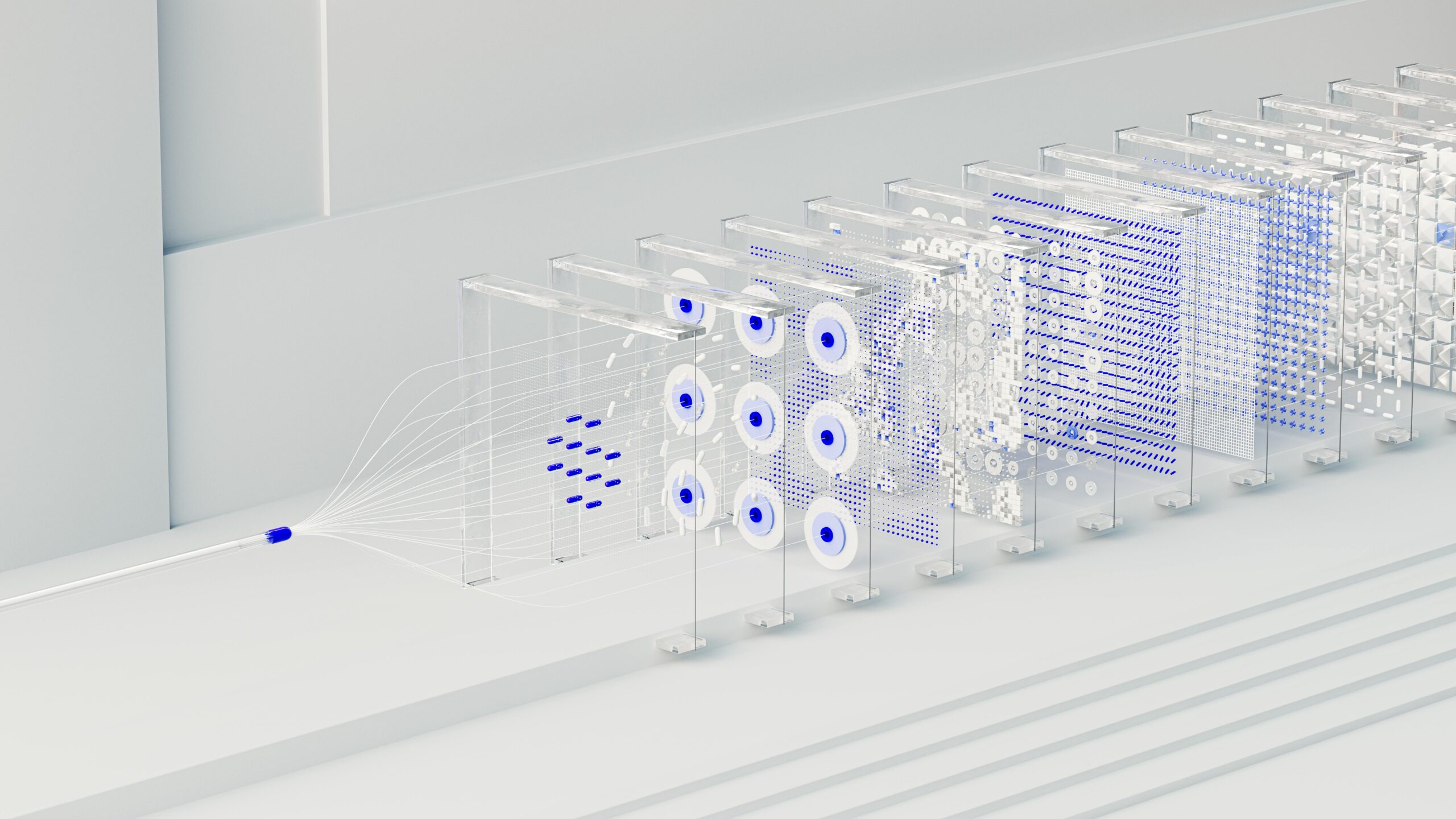

Three-dimensional visualizations combine spatial and temporal dimensions, creating powerful tools for understanding sensor network performance. These displays reveal patterns invisible in two-dimensional representations, such as traveling coverage gaps or time-varying bias related to environmental conditions.

💡 Real-World Impact Across Industries

The consequences of undetected sensor bias and coverage gaps extend far beyond abstract data quality concerns. Real-world applications demonstrate the critical importance of addressing these issues.

Manufacturing and Quality Control

Production facilities rely on sensor data to maintain quality standards and optimize processes. Biased temperature sensors in heat treatment operations produce parts that fail specifications. Coverage gaps in vibration monitoring miss bearing failures until catastrophic breakdowns occur. These problems translate directly to defective products, equipment damage, and production downtime.

One automotive manufacturer discovered that temperature sensor drift in their painting booth caused color variations across production runs. The bias developed gradually over months, creating subtle quality issues that customers noticed but quality control systems missed. Correcting the sensor bias and implementing regular calibration checks saved millions in warranty claims.

Environmental Monitoring Systems

Air quality networks protecting public health must provide accurate, comprehensive coverage. Sensor bias can underestimate pollution levels, leading to inadequate public warnings. Coverage gaps leave neighborhoods unmonitored, creating environmental justice concerns when vulnerable populations lack protection.

Climate research depends on long-term sensor data spanning decades. Small biases compound over time, potentially distorting conclusions about temperature trends, precipitation patterns, and ecosystem changes. Rigorous bias detection and correction protocols ensure that critical climate data maintains its scientific integrity.

Smart Building Operations

Modern buildings use extensive sensor networks to optimize energy consumption, maintain comfort, and ensure safety. Biased occupancy sensors waste energy by over-cooling empty spaces. Temperature sensor coverage gaps create hot and cold zones that occupants complain about. These problems increase operating costs and reduce satisfaction.

Building management systems aggregate data from hundreds or thousands of sensors. Subtle biases in individual sensors can skew zone-level calculations and building-wide optimization algorithms. Systematic analysis identifies problematic sensors before they significantly impact building performance.

🔧 Practical Strategies for Optimization

Addressing sensor bias and coverage gaps requires coordinated strategies combining technical solutions, operational procedures, and organizational commitment.

Calibration and Maintenance Protocols

Regular calibration schedules prevent drift from accumulating. Risk-based approaches prioritize critical sensors while extending intervals for less important measurements. Automated calibration systems reduce labor costs while improving consistency. Documentation tracks sensor performance over time, enabling predictive maintenance before accuracy degrades unacceptably.

Field calibration using portable reference standards brings accuracy checks to installed sensors rather than removing them for laboratory testing. This approach reduces downtime while providing verification in actual operating conditions. Mobile calibration teams can efficiently service distributed sensor networks.

Sensor Network Design Improvements

Strategic sensor placement eliminates coverage gaps during initial deployment rather than discovering them later. Computational fluid dynamics simulations guide air quality sensor positioning. Thermal modeling optimizes temperature sensor locations. Statistical power analysis determines minimum sensor densities for detecting events of specific magnitudes.

Redundancy and diversity improve reliability while enabling cross-validation. Deploying multiple sensor types measuring the same phenomenon provides independent verification. Overlapping coverage areas ensure that sensor failures don’t create monitoring blind spots. These design principles increase initial costs but dramatically improve long-term performance.

Data Processing and Correction Techniques

Software corrections can compensate for some types of sensor bias after data collection. Temperature compensation adjusts readings based on known thermal dependencies. Environmental corrections account for humidity, pressure, or other influences. These techniques extend sensor useful life and improve accuracy without hardware changes.

Machine learning algorithms detect subtle bias patterns that escape traditional analysis. Neural networks trained on high-quality reference data learn correction functions for specific sensor models or environmental conditions. Anomaly detection identifies individual sensors requiring attention within large networks.

📊 Monitoring System Performance Over Time

Continuous performance monitoring ensures that sensor systems maintain optimal accuracy despite changing conditions and aging components. Automated systems detect problems early while manual audits provide comprehensive verification.

Automated Quality Control Dashboards

Real-time monitoring dashboards track key performance indicators for sensor networks. Alert systems notify operators when readings exceed expected ranges, sensors stop reporting, or data patterns suggest calibration drift. These tools transform reactive maintenance into proactive system management.

Statistical process control charts adapted for sensor data reveal gradual performance degradation. Control limits based on historical data establish normal operating ranges. Sensors whose readings trend toward limits receive attention before they fail specification. This approach prevents minor issues from becoming major problems.

Regular System Audits and Reviews

Periodic comprehensive audits examine sensor system performance holistically. External experts provide fresh perspectives on coverage adequacy. Comparing original design assumptions against actual usage patterns identifies gaps. Stakeholder interviews reveal whether data quality meets user needs.

Documentation reviews ensure that maintenance records match actual practices. Audit trails track calibration certificates and sensor replacements. Configuration management verifies that installed sensors match system specifications. These administrative checks complement technical performance assessments.

🚀 Future Trends in Sensor Technology

Emerging technologies promise to reduce bias and coverage gaps while introducing new challenges requiring attention. Understanding these trends helps organizations prepare for evolving sensor landscapes.

Self-Calibrating and Adaptive Sensors

Next-generation sensors incorporate reference standards and calibration mechanisms directly into their designs. MEMS devices with built-in verification features detect drift automatically. Adaptive algorithms adjust for environmental influences in real-time. These innovations reduce maintenance requirements while improving accuracy.

Wireless sensor networks with cooperative calibration capabilities verify accuracy through peer comparison. Sensors communicate to identify outliers and estimate bias through consensus algorithms. Distributed intelligence reduces dependence on centralized validation while improving network robustness.

Artificial Intelligence Integration

AI-powered sensor fusion combines data from multiple sources to create comprehensive situational awareness exceeding any individual sensor’s capabilities. Machine learning fills coverage gaps through intelligent interpolation based on physical principles and historical patterns. These techniques extract maximum value from existing sensor infrastructure.

Predictive maintenance algorithms analyze sensor performance trends to schedule interventions before failures occur. Digital twins create virtual representations of sensor networks, enabling simulation of different coverage strategies and bias correction approaches. These tools optimize sensor system design and operation.

🎓 Building Organizational Capability

Technical solutions alone cannot ensure optimal sensor system performance. Organizations must develop institutional knowledge, appropriate skills, and cultural commitment to data quality.

Training and Education Programs

Personnel at all levels need understanding appropriate to their roles. Operators require basic sensor maintenance skills and awareness of common failure modes. Analysts need statistical techniques for detecting bias and coverage gaps. Managers must appreciate the business impact of sensor data quality to support necessary investments.

Hands-on training with actual sensor systems builds practical competence beyond theoretical knowledge. Workshops demonstrating bias effects and coverage gap impacts create visceral understanding. Case studies from similar organizations provide concrete examples of problems and solutions.

Cross-Functional Collaboration

Optimal sensor system performance requires cooperation between IT, operations, maintenance, and data science teams. Breaking down organizational silos enables comprehensive approaches to bias detection and coverage optimization. Regular coordination meetings ensure that all stakeholders understand current challenges and improvement initiatives.

Establishing clear accountability for sensor data quality prevents problems from falling through organizational cracks. Designated owners for sensor networks drive continuous improvement efforts. Performance metrics tied to data quality create incentives for maintaining optimal sensor system performance.

🌟 Achieving Excellence Through Vigilance

Sensor bias and coverage gaps represent persistent challenges requiring ongoing attention rather than one-time fixes. Organizations that treat sensor data quality as a continuous improvement journey rather than a project achieve superior results. Systematic analysis reveals hidden problems. Comprehensive strategies address root causes rather than symptoms. Cultural commitment sustains performance over time.

The investment in understanding and optimizing sensor systems pays dividends across multiple dimensions. Better data enables better decisions. Reduced false alarms lower operational costs. Improved coverage enhances safety and compliance. Organizations embracing these principles position themselves for success in increasingly data-driven environments where sensor accuracy and comprehensiveness directly impact competitive advantage.

By uncovering the secrets hidden in sensor networks and addressing both bias and coverage gaps systematically, organizations transform raw measurements into reliable intelligence. This foundation supports confident decision-making, efficient operations, and continuous improvement across all application domains. The journey toward optimal sensor performance begins with acknowledging these challenges and committing to rigorous analytical approaches that reveal truth hiding within the data.

Toni Santos is a bioacoustic researcher and conservation technologist specializing in the study of animal communication systems, acoustic monitoring infrastructures, and the sonic landscapes embedded in natural ecosystems. Through an interdisciplinary and sensor-focused lens, Toni investigates how wildlife encodes behavior, territory, and survival into the acoustic world — across species, habitats, and conservation challenges. His work is grounded in a fascination with animals not only as lifeforms, but as carriers of acoustic meaning. From endangered vocalizations to soundscape ecology and bioacoustic signal patterns, Toni uncovers the technological and analytical tools through which researchers preserve their understanding of the acoustic unknown. With a background in applied bioacoustics and conservation monitoring, Toni blends signal analysis with field-based research to reveal how sounds are used to track presence, monitor populations, and decode ecological knowledge. As the creative mind behind Nuvtrox, Toni curates indexed communication datasets, sensor-based monitoring studies, and acoustic interpretations that revive the deep ecological ties between fauna, soundscapes, and conservation science. His work is a tribute to: The archived vocal diversity of Animal Communication Indexing The tracked movements of Applied Bioacoustics Tracking The ecological richness of Conservation Soundscapes The layered detection networks of Sensor-based Monitoring Whether you're a bioacoustic analyst, conservation researcher, or curious explorer of acoustic ecology, Toni invites you to explore the hidden signals of wildlife communication — one call, one sensor, one soundscape at a time.