Acoustic sensors play a critical role in modern technology, from smartphones to industrial monitoring systems, making their calibration and quality control essential for reliable performance.

🎯 Understanding the Foundation of Acoustic Sensor Technology

Acoustic sensors have become ubiquitous in our daily lives, yet their complexity often goes unnoticed. These sophisticated devices convert sound waves into electrical signals, enabling everything from voice recognition to structural health monitoring. The accuracy of these conversions depends entirely on proper calibration and rigorous quality control processes.

The journey toward perfect pitch in acoustic sensor performance begins with understanding the fundamental principles that govern their operation. Sound pressure levels, frequency response, sensitivity, and dynamic range all contribute to a sensor’s ability to accurately capture acoustic information. Without proper calibration, even the most advanced sensor technology can produce unreliable results that compromise entire systems.

Manufacturing acoustic sensors requires precision engineering at every stage. From the selection of piezoelectric materials to the design of diaphragms and housing, each component affects the final performance characteristics. This complexity makes calibration and quality control not just important, but absolutely critical for ensuring consistent, reliable output across different operating conditions.

🔬 The Science Behind Acoustic Sensor Calibration

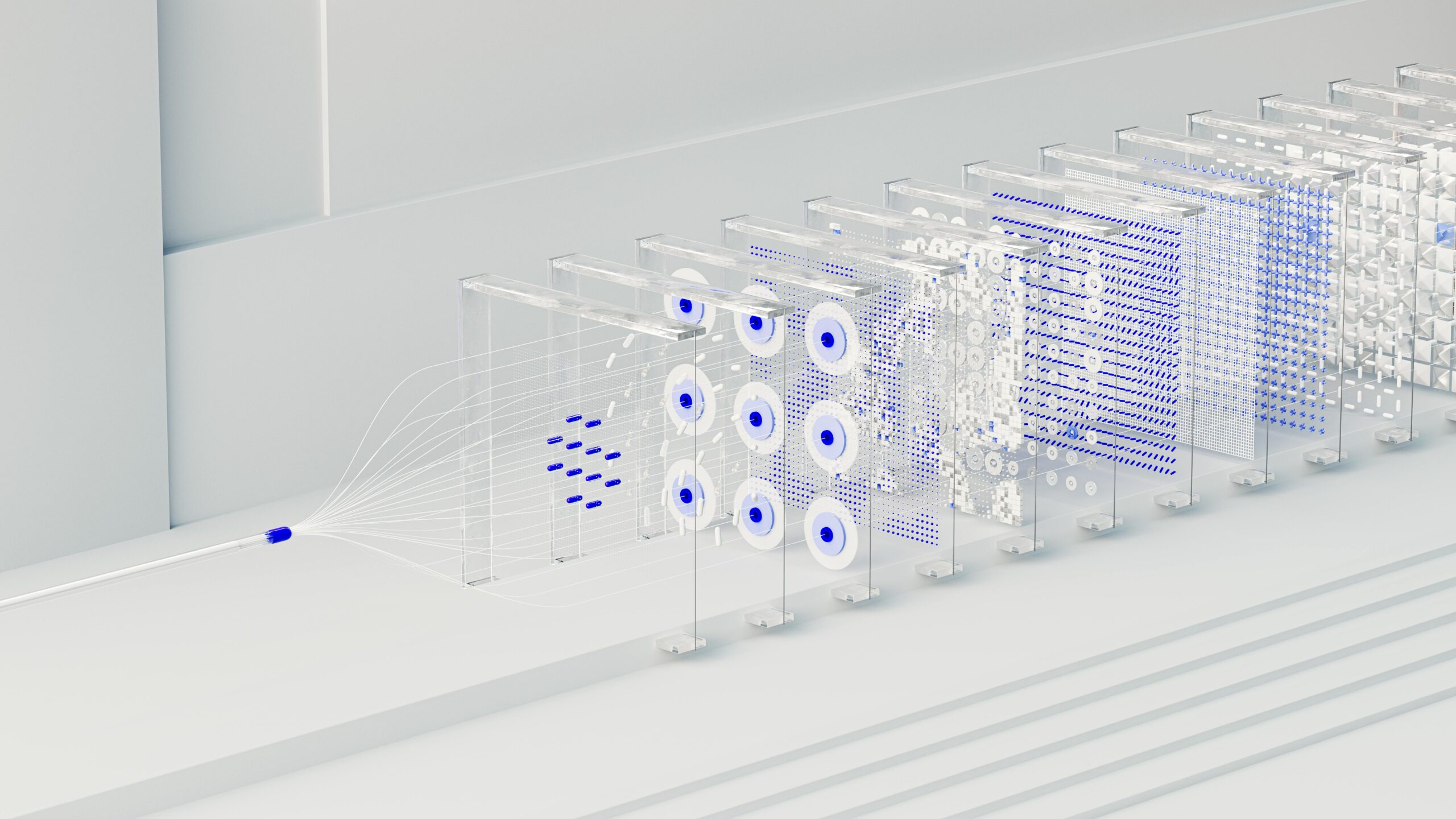

Calibration establishes a known relationship between the physical stimulus (sound pressure) and the sensor’s electrical output. This process involves exposing the sensor to carefully controlled acoustic environments and measuring its response across various frequencies and amplitudes. The resulting data creates a calibration curve that allows for accurate measurement conversion.

Primary calibration methods utilize reference standards traceable to national metrology institutes. These standards typically employ reciprocity calibration techniques, which use the reversible nature of certain transducers to establish absolute sensitivity without requiring a reference sound field. This sophisticated approach ensures the highest accuracy levels for laboratory-grade reference microphones.

Secondary calibration methods offer more practical approaches for production environments. These techniques compare sensors against calibrated reference microphones in controlled acoustic chambers. While slightly less accurate than primary methods, secondary calibration provides sufficient precision for most commercial applications while being more cost-effective and time-efficient.

Key Calibration Parameters to Monitor

Sensitivity represents the most fundamental calibration parameter, defining the electrical output produced per unit of sound pressure. Typically expressed in millivolts per Pascal (mV/Pa) or decibels relative to one volt per Pascal (dB re 1V/Pa), sensitivity calibration ensures consistent amplitude measurements across different sensors.

Frequency response calibration maps how a sensor responds to different sound frequencies. Ideal sensors maintain flat response across their specified frequency range, but real-world devices exhibit variations that must be characterized and compensated. This calibration data enables correction algorithms that improve measurement accuracy across the entire frequency spectrum.

Phase response, though often overlooked, becomes critical in applications requiring precise timing information or multi-sensor arrays. Phase calibration ensures that sensors accurately preserve the temporal relationships between different frequency components, essential for spatial audio, beamforming, and acoustic localization applications.

⚙️ Implementing Robust Quality Control Protocols

Quality control extends beyond initial calibration to encompass comprehensive testing throughout the manufacturing process. Statistical process control methods help identify variations before they become systematic problems, ensuring consistent quality across production batches. These protocols must balance thoroughness with efficiency to maintain economic viability.

Incoming material inspection forms the first line of defense against quality issues. Raw materials, particularly piezoelectric elements and diaphragm materials, must meet strict specifications for physical and electrical properties. Early detection of substandard materials prevents waste and maintains production efficiency.

In-process testing catches problems during assembly rather than after completion. Automated testing stations can measure intermediate characteristics such as diaphragm tension, electrical impedance, and preliminary acoustic response. This approach reduces scrap rates and provides valuable feedback for process optimization.

Environmental Testing for Real-World Performance

Temperature cycling reveals how sensors perform across their specified operating range. Acoustic sensitivity often varies with temperature due to changes in material properties and mechanical dimensions. Quality control protocols must verify that these variations remain within acceptable limits and that calibration data accurately accounts for thermal effects.

Humidity exposure testing ensures sensors maintain performance in varying moisture conditions. Water ingress can dramatically alter acoustic properties and cause electrical failures. Proper sealing designs must be verified through rigorous environmental chamber testing that simulates real-world conditions.

Vibration and shock testing confirms mechanical robustness for applications in challenging environments. Industrial monitoring systems, automotive applications, and portable devices all subject sensors to mechanical stresses that could degrade performance or cause failure. Quality control must verify adequate resilience through standardized mechanical testing protocols.

📊 Advanced Calibration Techniques for Modern Applications

Digital calibration methods leverage embedded processing capabilities to implement sophisticated correction algorithms. By storing calibration coefficients in non-volatile memory, sensors can automatically compensate for frequency response variations, temperature effects, and aging characteristics. This approach enables higher accuracy from lower-cost transducer elements.

Array calibration addresses the unique challenges of multi-microphone systems used in beamforming and spatial audio applications. Beyond individual sensor calibration, array systems require precise characterization of inter-element phase matching, geometric positioning accuracy, and coherence across the frequency range. Specialized anechoic chamber measurements with robotic positioning systems enable the necessary precision.

In-situ calibration techniques allow field verification without removing sensors from their installed locations. Reference sound sources with known output characteristics enable periodic calibration checks that detect drift or degradation. This capability proves especially valuable for permanent installations in industrial or environmental monitoring applications.

Automated Calibration Systems

Modern production environments increasingly rely on fully automated calibration stations that combine acoustic stimulus generation, response measurement, data analysis, and certificate generation. These systems dramatically improve throughput while ensuring consistent, repeatable calibration procedures that eliminate human error.

Automated systems typically employ computer-controlled pistonphones or electrostatic actuators to generate precise acoustic stimuli. High-resolution data acquisition systems capture sensor responses with minimal noise and distortion. Sophisticated software analyzes the data, applies appropriate standards, and generates calibration certificates with full traceability.

Integration with manufacturing execution systems enables real-time quality monitoring and statistical analysis. Automated systems can flag sensors falling outside specification limits, track calibration trends over time, and provide early warning of process drift. This data-driven approach supports continuous improvement initiatives and reduces quality escapes.

🛠️ Troubleshooting Common Calibration Challenges

Acoustic interference from environmental noise complicates calibration measurements, especially at low frequencies and high sensitivities. Proper acoustic isolation through anechoic chambers or specialized calibration enclosures minimizes background noise influence. When perfect isolation proves impractical, signal averaging techniques can extract the sensor response from noise-contaminated measurements.

Electrical noise and electromagnetic interference affect measurement accuracy, particularly for low-level signals. Proper shielding, grounding practices, and balanced signal transmission minimize these effects. Calibration facilities must maintain electromagnetic cleanliness through careful equipment selection and layout planning.

Mechanical mounting effects alter sensor response characteristics in ways that may not appear during free-field calibration. The acoustic impedance of mounting surfaces, cavity resonances, and vibration coupling all influence real-world performance. Quality control protocols should include representative mounting condition testing when possible.

Aging and Drift Considerations

All acoustic sensors experience gradual performance changes over time due to material aging, contamination, and mechanical wear. Regular recalibration intervals must be established based on stability testing data and application requirements. Critical measurement applications may require annual or even more frequent recalibration to maintain accuracy.

Accelerated aging tests help predict long-term stability by exposing sensors to elevated temperature, humidity, and acoustic stress levels. These tests enable reliability predictions and appropriate warranty periods. Understanding failure modes guides design improvements that enhance longevity.

🌐 Industry Standards and Compliance Requirements

International standards provide the framework for acoustic sensor calibration and quality control. IEC 61094 series standards specify methods for laboratory-grade microphone calibration, while IEC 60942 covers field calibration equipment. Compliance with these standards ensures measurement traceability and international recognition of calibration certificates.

Industry-specific standards impose additional requirements for particular applications. For example, aerospace applications may require compliance with military standards, while consumer electronics follow industry consortia specifications. Understanding applicable standards early in the development process prevents costly redesigns and certification delays.

ISO 9001 quality management systems provide the organizational framework for maintaining consistent calibration and quality control processes. Documentation requirements, internal audits, and management reviews ensure that procedures remain effective and continuously improve. Many customers now require ISO certification as a prerequisite for vendor qualification.

💡 Emerging Technologies Shaping Future Calibration Approaches

Machine learning algorithms increasingly augment traditional calibration methods by identifying complex patterns in sensor behavior that resist conventional modeling. Neural networks trained on extensive calibration datasets can predict sensor response under varied conditions, potentially reducing the need for exhaustive environmental testing while improving accuracy.

MEMS (Micro-Electro-Mechanical Systems) technology enables miniature acoustic sensors with built-in self-test and calibration capabilities. On-chip reference structures and embedded signal processing allow for periodic automatic calibration verification without external equipment. This autonomy particularly benefits remote or inaccessible installations.

Blockchain technology offers potential solutions for calibration certificate management and traceability. Immutable records of calibration history, stored in distributed ledgers, could prevent certificate fraud and simplify audit trails. While still emerging, this application may transform how industries manage metrological traceability.

🎓 Building Expertise in Acoustic Sensor Quality Assurance

Developing skilled personnel remains critical for maintaining high-quality calibration and quality control programs. Formal training in acoustics, metrology, and quality management provides the theoretical foundation. However, practical experience with specific equipment and procedures proves equally important for developing true expertise.

Cross-functional collaboration enhances quality outcomes by bringing together diverse perspectives. Design engineers, production technicians, quality specialists, and application engineers each contribute unique insights that strengthen overall sensor performance. Regular communication channels and joint problem-solving sessions foster this beneficial collaboration.

Continuous learning keeps teams current with evolving technologies and methods. Industry conferences, technical publications, and professional organization memberships provide exposure to cutting-edge developments. Organizations that prioritize learning create competitive advantages through superior technical capabilities.

🚀 Optimizing Calibration for Specific Application Domains

Consumer electronics applications prioritize cost-effective calibration methods that balance accuracy with production economics. Automated test equipment, statistical sampling plans, and streamlined procedures enable high-volume manufacturing while maintaining acceptable quality levels. The key lies in understanding which specifications truly impact user experience and focusing calibration efforts accordingly.

Industrial monitoring applications demand long-term stability and reliability in harsh environments. More rigorous calibration procedures, extended environmental testing, and shorter recalibration intervals justify the higher costs through reduced downtime and improved safety. Documenting calibration traceability becomes critical for regulatory compliance in many industries.

Scientific research applications require the highest possible accuracy and comprehensive uncertainty analysis. Primary calibration methods, climate-controlled environments, and meticulous documentation support demanding measurement requirements. The investment in premium calibration capabilities enables discoveries that would otherwise remain obscured by measurement uncertainty.

🔄 Creating Sustainable Calibration Programs

Long-term program success requires balancing technical requirements with practical constraints. Equipment investments, facility requirements, staffing needs, and ongoing consumable costs all factor into program sustainability. Careful planning ensures capabilities match needs without unnecessary excess that wastes resources.

Maintaining calibration equipment requires dedicated attention to preserve accuracy and reliability. Reference microphones, pistonphones, and measurement instrumentation all need regular verification against higher-level standards. Equipment maintenance schedules, spare parts inventory, and repair service arrangements prevent disruptions to production schedules.

Documentation systems preserve institutional knowledge and support compliance requirements. Calibration procedures, equipment manuals, training materials, and historical data must be organized for easy access and protected against loss. Modern document management systems streamline these tasks while improving information accessibility.

The pursuit of perfect pitch in acoustic sensor calibration and quality control represents an ongoing journey rather than a final destination. As applications become more demanding and technologies continue evolving, calibration methodologies must adapt to meet new challenges. Organizations that invest in robust calibration infrastructure, skilled personnel, and continuous improvement processes position themselves for long-term success in increasingly competitive markets.

Mastering these complex disciplines requires commitment, expertise, and attention to detail. However, the rewards extend far beyond meeting specifications—they enable innovations that enhance human experiences, improve safety, and advance scientific understanding. Whether developing the next generation of consumer devices or deploying critical monitoring systems, excellence in acoustic sensor calibration and quality control provides the foundation for transformative achievements.

Toni Santos is a bioacoustic researcher and conservation technologist specializing in the study of animal communication systems, acoustic monitoring infrastructures, and the sonic landscapes embedded in natural ecosystems. Through an interdisciplinary and sensor-focused lens, Toni investigates how wildlife encodes behavior, territory, and survival into the acoustic world — across species, habitats, and conservation challenges. His work is grounded in a fascination with animals not only as lifeforms, but as carriers of acoustic meaning. From endangered vocalizations to soundscape ecology and bioacoustic signal patterns, Toni uncovers the technological and analytical tools through which researchers preserve their understanding of the acoustic unknown. With a background in applied bioacoustics and conservation monitoring, Toni blends signal analysis with field-based research to reveal how sounds are used to track presence, monitor populations, and decode ecological knowledge. As the creative mind behind Nuvtrox, Toni curates indexed communication datasets, sensor-based monitoring studies, and acoustic interpretations that revive the deep ecological ties between fauna, soundscapes, and conservation science. His work is a tribute to: The archived vocal diversity of Animal Communication Indexing The tracked movements of Applied Bioacoustics Tracking The ecological richness of Conservation Soundscapes The layered detection networks of Sensor-based Monitoring Whether you're a bioacoustic analyst, conservation researcher, or curious explorer of acoustic ecology, Toni invites you to explore the hidden signals of wildlife communication — one call, one sensor, one soundscape at a time.