Modern industries face mounting pressure to maintain operational continuity while minimizing downtime. Remote equipment failure detection has emerged as a game-changing solution for businesses seeking competitive advantage.

🔍 The Critical Importance of Proactive Equipment Monitoring

Equipment failures don’t announce themselves with advance warning—or do they? The reality is that most machinery exhibits subtle signs of deterioration long before catastrophic breakdowns occur. Traditional maintenance approaches relied on scheduled inspections and reactive repairs, resulting in unexpected downtime, production losses, and spiraling maintenance costs.

Remote monitoring technology transforms this paradigm entirely. By implementing sophisticated sensor networks and analytics platforms, organizations can detect anomalies in real-time, predict potential failures, and intervene before problems escalate. This shift from reactive to predictive maintenance represents one of the most significant operational improvements available to modern enterprises.

The financial implications are substantial. Research indicates that unplanned downtime costs industrial manufacturers an estimated $50 billion annually. When equipment fails unexpectedly, the consequences ripple throughout the entire operation—halted production lines, missed delivery deadlines, disappointed customers, and emergency repair expenses that far exceed planned maintenance budgets.

💡 Understanding Remote Equipment Failure Detection Technology

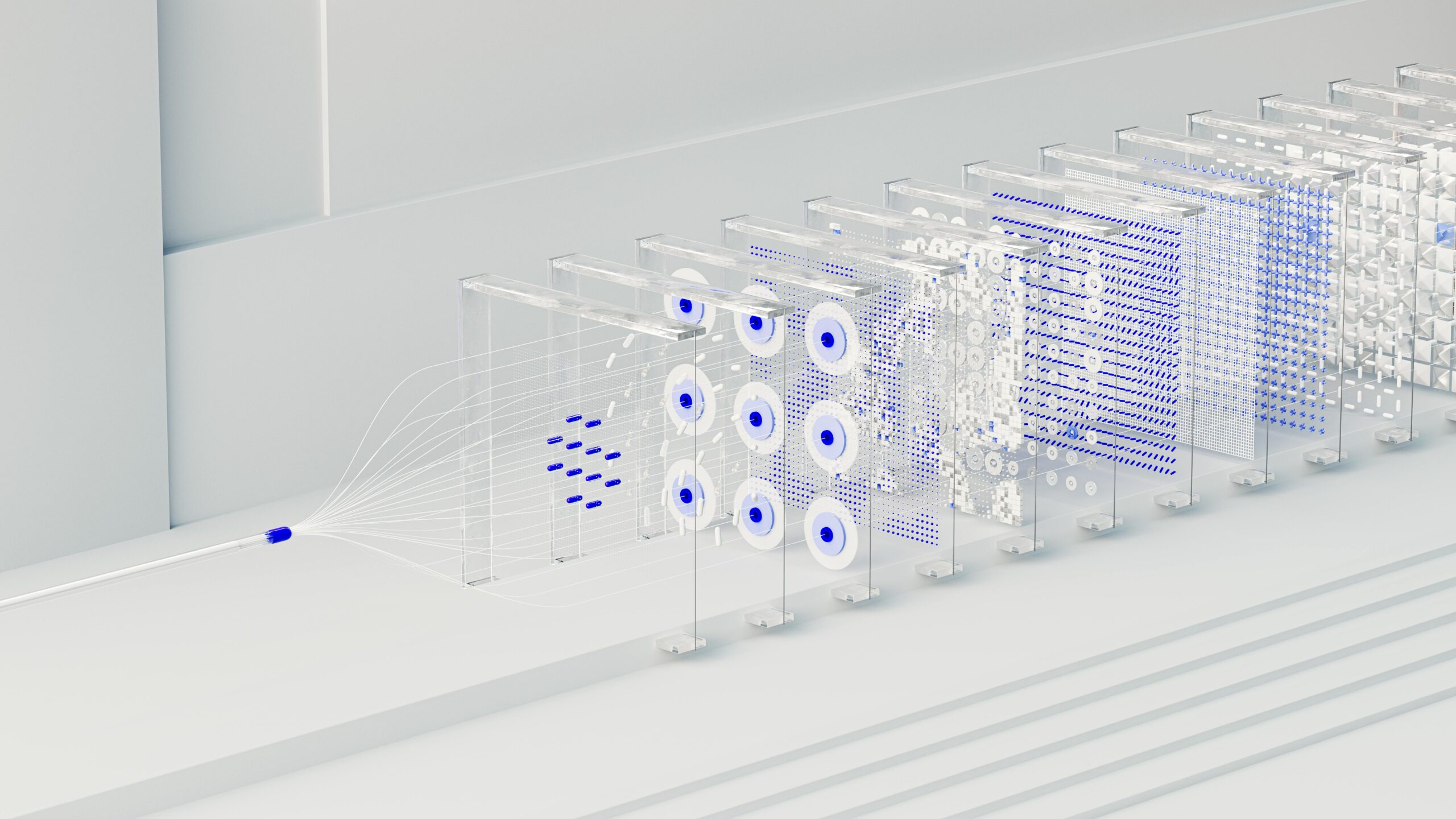

Remote equipment monitoring systems leverage Internet of Things (IoT) sensors, machine learning algorithms, and cloud-based analytics to provide comprehensive visibility into equipment health. These systems continuously collect data on various parameters including vibration, temperature, pressure, electrical current, acoustic emissions, and operational speed.

The collected data streams to centralized platforms where sophisticated algorithms analyze patterns, compare current performance against baseline metrics, and identify deviations that signal potential problems. Advanced systems employ artificial intelligence to recognize complex patterns that human operators might miss, improving detection accuracy over time as the machine learning models refine themselves.

Key Components of Remote Monitoring Systems

A comprehensive remote monitoring infrastructure consists of several integrated components working in concert:

- Wireless Sensors: Compact devices attached to equipment that measure specific parameters continuously

- Edge Computing Devices: Local processing units that perform initial data filtering and analysis

- Communication Networks: Reliable connectivity solutions including cellular, Wi-Fi, or dedicated industrial networks

- Cloud Platforms: Scalable infrastructure for data storage, advanced analytics, and visualization

- Alert Systems: Automated notification mechanisms that inform relevant personnel of detected anomalies

- Dashboard Interfaces: User-friendly visualization tools that present complex data in actionable formats

📊 Identifying the Warning Signs: What to Monitor

Different equipment types exhibit unique failure signatures. Understanding which parameters to monitor for specific machinery categories enhances detection effectiveness and reduces false positives that can overwhelm maintenance teams.

Rotating Equipment

Motors, pumps, compressors, and turbines benefit tremendously from vibration analysis. Changes in vibration patterns reveal bearing wear, misalignment, imbalance, and looseness. Temperature monitoring complements vibration data by identifying lubrication problems, electrical issues, or excessive friction before components seize.

Electrical Systems

Power consumption anomalies, voltage fluctuations, harmonic distortions, and thermal signatures provide early warning of electrical component degradation. Monitoring these parameters prevents costly electrical failures and reduces fire risks associated with deteriorating connections or overloaded circuits.

Hydraulic and Pneumatic Systems

Pressure fluctuations, flow rate variations, and fluid contamination levels indicate seal failures, valve problems, or component wear. Oil analysis through remote sensors detects particle contamination and chemical degradation that compromise system performance.

Heat Exchangers and Cooling Systems

Temperature differentials, flow rates, and pressure drops reveal fouling, scaling, or leakage issues. Early detection prevents efficiency losses and protects downstream equipment from operating outside design parameters.

🚀 Implementing Remote Monitoring: A Strategic Approach

Successful implementation requires careful planning and phased execution. Organizations that rush deployment without proper strategy often struggle with data overload, poor integration, and underwhelming return on investment.

Assessment and Planning

Begin by identifying critical assets where failures create the most significant operational or financial impact. Conduct a thorough audit of existing equipment, maintenance history, and current monitoring capabilities. This assessment reveals gaps and prioritizes monitoring investments toward assets with the highest risk-adjusted returns.

Establish clear objectives that align with broader operational goals. Whether reducing unplanned downtime by a specific percentage, extending equipment lifespan, or optimizing maintenance resource allocation, defined metrics enable progress tracking and ROI calculation.

Technology Selection

The monitoring solution marketplace offers numerous options ranging from specialized single-parameter sensors to comprehensive enterprise platforms. Selection criteria should include:

- Compatibility with existing equipment and infrastructure

- Scalability to accommodate future expansion

- Integration capabilities with maintenance management systems

- Data security and privacy protections

- Vendor support quality and long-term viability

- Total cost of ownership including hardware, connectivity, and platform subscriptions

Pilot Programs

Deploy initial monitoring systems on a limited scale to validate technology performance, refine alerting thresholds, and build organizational competency before full-scale rollout. Pilot programs reveal implementation challenges in controlled environments where adjustments can be made without risking broader operations.

⚙️ Maximizing Value Through Data-Driven Maintenance Strategies

Remote monitoring technology generates value only when organizations act on the insights it provides. Integrating monitoring data with maintenance workflows transforms raw information into operational improvements.

Predictive Maintenance Scheduling

Traditional time-based maintenance either services equipment too frequently (wasting resources) or too infrequently (risking failures). Condition-based scheduling triggered by actual equipment health optimizes maintenance timing, reducing unnecessary interventions while preventing unexpected breakdowns.

Predictive algorithms analyze historical failure patterns and current condition data to estimate remaining useful life with increasing accuracy. This precision enables organizations to schedule maintenance during planned downtime windows, coordinate spare parts procurement, and allocate technician resources efficiently.

Root Cause Analysis

When failures do occur, comprehensive monitoring data provides forensic evidence that reveals underlying causes rather than just symptoms. Understanding why equipment failed enables corrective actions that prevent recurrence—whether through design modifications, operational procedure changes, or improved maintenance practices.

Performance Optimization

Beyond failure prevention, continuous monitoring identifies opportunities to optimize equipment performance. Recognizing efficiency degradation prompts interventions that restore optimal operating conditions, reducing energy consumption and maximizing throughput.

💼 Real-World Applications Across Industries

Remote equipment monitoring delivers tangible benefits across diverse industrial sectors, each adapting the technology to address specific operational challenges.

Manufacturing Operations

Production facilities depend on synchronized equipment networks where single-point failures cascade throughout the process. Remote monitoring protects against these vulnerabilities by identifying weak links before they break, maintaining production continuity that preserves customer commitments and revenue streams.

Energy and Utilities

Power generation facilities, transmission networks, and water treatment plants operate critical infrastructure that serves entire communities. Remote monitoring ensures reliability while enabling operators to manage geographically dispersed assets from centralized control centers, optimizing response times and resource deployment.

Transportation and Logistics

Fleet vehicles, material handling equipment, and warehouse automation systems benefit from remote diagnostics that minimize service interruptions. Monitoring systems detect developing problems before vehicles break down on routes or critical distribution center equipment fails during peak operational periods.

Oil and Gas Operations

Remote and hazardous production environments make equipment accessibility challenging and dangerous. Wireless monitoring systems provide visibility into wellhead equipment, pipeline infrastructure, and processing facilities without requiring personnel presence in hostile locations, improving both operational reliability and worker safety.

📱 Mobile Connectivity: Monitoring Equipment from Anywhere

Modern remote monitoring platforms offer mobile applications that extend system access beyond desktop computers to smartphones and tablets. This mobility empowers maintenance teams, engineers, and operations managers to monitor equipment health, receive alerts, and coordinate responses regardless of their physical location.

Mobile interfaces display real-time equipment status, historical trend data, and analytical insights in formats optimized for smaller screens. Push notifications ensure critical alerts reach responsible personnel immediately, even outside normal working hours, enabling rapid response to developing problems.

The ability to access monitoring data remotely proves particularly valuable for organizations with distributed assets, multi-site operations, or personnel who travel regularly. Equipment specialists can provide expert diagnosis and guidance without traveling to physical locations, reducing response times and associated costs.

🔐 Addressing Security Concerns in Connected Equipment

As equipment monitoring systems connect operational technology networks to cloud platforms and mobile devices, cybersecurity considerations become paramount. Industrial control systems historically operated in isolation, but connectivity introduces vulnerabilities that require robust protection strategies.

Comprehensive security frameworks implement multiple defensive layers including encrypted data transmission, secure authentication protocols, role-based access controls, and regular security audits. Organizations must balance accessibility with protection, ensuring authorized users can access needed information while preventing unauthorized intrusion.

Vendor selection should prioritize partners demonstrating commitment to security best practices, regular vulnerability assessments, and transparent incident response protocols. Understanding where data resides, who can access it, and how it’s protected forms essential due diligence in monitoring system deployment.

🎯 Measuring Success: Key Performance Indicators

Quantifying remote monitoring impact validates investment decisions and guides continuous improvement efforts. Organizations should track metrics that reflect both operational and financial benefits:

| Metric | Baseline Comparison | Target Improvement |

|---|---|---|

| Unplanned Downtime Hours | Pre-implementation average | 30-50% reduction |

| Mean Time Between Failures | Historical equipment records | 20-40% increase |

| Maintenance Cost per Unit Produced | Previous fiscal period | 15-25% decrease |

| Emergency Repair Incidents | Annual occurrence rate | 40-60% reduction |

| Equipment Utilization Rate | Operational efficiency baseline | 10-20% improvement |

Beyond quantitative metrics, qualitative benefits include improved workforce morale as technicians transition from firefighting failures to planned maintenance activities, enhanced safety through reduced emergency repair situations, and increased organizational confidence in operational reliability.

🌟 Overcoming Implementation Challenges

Despite compelling benefits, organizations encounter obstacles during remote monitoring deployment. Anticipating these challenges and preparing mitigation strategies accelerates successful adoption.

Organizational Resistance

Maintenance personnel accustomed to traditional approaches may view monitoring technology skeptically, perceiving it as unnecessary complexity or even threats to job security. Effective change management emphasizes how technology augments rather than replaces human expertise, enabling technicians to focus on high-value activities rather than routine inspections.

Integration Complexity

Legacy equipment lacks built-in connectivity, requiring retrofit sensor installations that may prove technically challenging. Working with experienced integration partners who understand both monitoring technology and specific equipment types smooths implementation and prevents costly mistakes.

Data Interpretation

Sophisticated monitoring systems generate substantial data volumes that can overwhelm teams lacking analytical expertise. Investing in training, starting with simplified alert configurations, and gradually expanding analytical sophistication builds organizational capability over time.

🔮 Future Trends Shaping Equipment Monitoring

Remote monitoring technology continues evolving rapidly, with emerging capabilities promising even greater operational benefits. Artificial intelligence advances enable increasingly sophisticated pattern recognition that detects subtle failure signatures earlier and with fewer false positives.

Edge computing development pushes more analytical processing to local devices, reducing latency and bandwidth requirements while enabling continued operation during connectivity interruptions. This distributed intelligence architecture enhances system resilience and responsiveness.

Digital twin technology creates virtual equipment replicas that simulate performance under various conditions, enabling “what-if” scenario analysis and optimization strategies impossible with physical equipment alone. These virtual models, continuously updated with real monitoring data, become powerful tools for understanding equipment behavior and planning improvements.

Augmented reality interfaces will soon overlay monitoring data onto physical equipment during maintenance activities, providing technicians with contextual information precisely when and where they need it. This convergence of physical and digital information streamlines troubleshooting and repair processes.

🏆 Competitive Advantages of Proactive Equipment Management

Organizations that master remote equipment monitoring gain significant competitive advantages beyond immediate operational benefits. Reliability becomes a differentiator in industries where customers value consistent performance and on-time delivery. The ability to guarantee service levels and production commitments strengthens market position and justifies premium pricing.

Operational data accumulated through monitoring programs provides insights that inform strategic decisions about equipment replacement timing, capital investment priorities, and process improvement opportunities. This intelligence guides resource allocation toward initiatives delivering maximum returns.

Sustainability initiatives benefit from monitoring systems that optimize energy consumption, reduce waste from unnecessary maintenance, and extend equipment lifespan. These environmental improvements increasingly influence customer preferences and regulatory compliance requirements.

🎓 Building Internal Capabilities for Long-Term Success

Technology deployment represents only the beginning of the remote monitoring journey. Sustained value creation requires developing organizational capabilities that leverage monitoring insights effectively.

Cross-functional teams including maintenance, operations, engineering, and IT collaboration ensure monitoring systems align with actual needs rather than theoretical capabilities. Regular review sessions that examine alert effectiveness, false positive rates, and missed detections drive continuous refinement.

Formal training programs build competency across all organizational levels—from executives understanding strategic implications to technicians interpreting sensor data and responding appropriately. This capability development transforms monitoring from a technology project into a core operational competency.

Documentation of lessons learned, failure case studies, and best practices creates institutional knowledge that survives personnel changes and guides future decisions. Organizations that systematically capture and share monitoring insights maximize return on their technology investments.

✅ Taking the First Steps Toward Seamless Operations

The journey toward comprehensive remote equipment monitoring begins with commitment to operational excellence and willingness to embrace data-driven maintenance approaches. Start by identifying critical equipment where failures create the most significant impact, then deploy pilot monitoring systems that demonstrate value and build organizational confidence.

Partner with experienced technology providers who understand your industry’s specific challenges and can guide implementation from planning through optimization. Invest in personnel training that builds analytical skills and fosters cultural acceptance of predictive maintenance philosophies.

Monitor progress against established metrics, celebrate successes, and learn from setbacks. Continuous improvement mindsets that view monitoring systems as evolving capabilities rather than static installations unlock maximum long-term value.

The competitive landscape increasingly favors organizations that detect and address equipment problems before they disrupt operations. Remote monitoring technology provides the visibility, insights, and responsiveness needed to maintain this advantage, transforming maintenance from a cost center into a strategic differentiator that drives operational excellence and business success.

Toni Santos is a bioacoustic researcher and conservation technologist specializing in the study of animal communication systems, acoustic monitoring infrastructures, and the sonic landscapes embedded in natural ecosystems. Through an interdisciplinary and sensor-focused lens, Toni investigates how wildlife encodes behavior, territory, and survival into the acoustic world — across species, habitats, and conservation challenges. His work is grounded in a fascination with animals not only as lifeforms, but as carriers of acoustic meaning. From endangered vocalizations to soundscape ecology and bioacoustic signal patterns, Toni uncovers the technological and analytical tools through which researchers preserve their understanding of the acoustic unknown. With a background in applied bioacoustics and conservation monitoring, Toni blends signal analysis with field-based research to reveal how sounds are used to track presence, monitor populations, and decode ecological knowledge. As the creative mind behind Nuvtrox, Toni curates indexed communication datasets, sensor-based monitoring studies, and acoustic interpretations that revive the deep ecological ties between fauna, soundscapes, and conservation science. His work is a tribute to: The archived vocal diversity of Animal Communication Indexing The tracked movements of Applied Bioacoustics Tracking The ecological richness of Conservation Soundscapes The layered detection networks of Sensor-based Monitoring Whether you're a bioacoustic analyst, conservation researcher, or curious explorer of acoustic ecology, Toni invites you to explore the hidden signals of wildlife communication — one call, one sensor, one soundscape at a time.