Deploying sensors in extreme conditions demands careful planning, robust equipment, and strategic implementation to ensure reliable data collection and long-term operational success.

🌡️ Understanding the Challenge of Harsh Environment Deployments

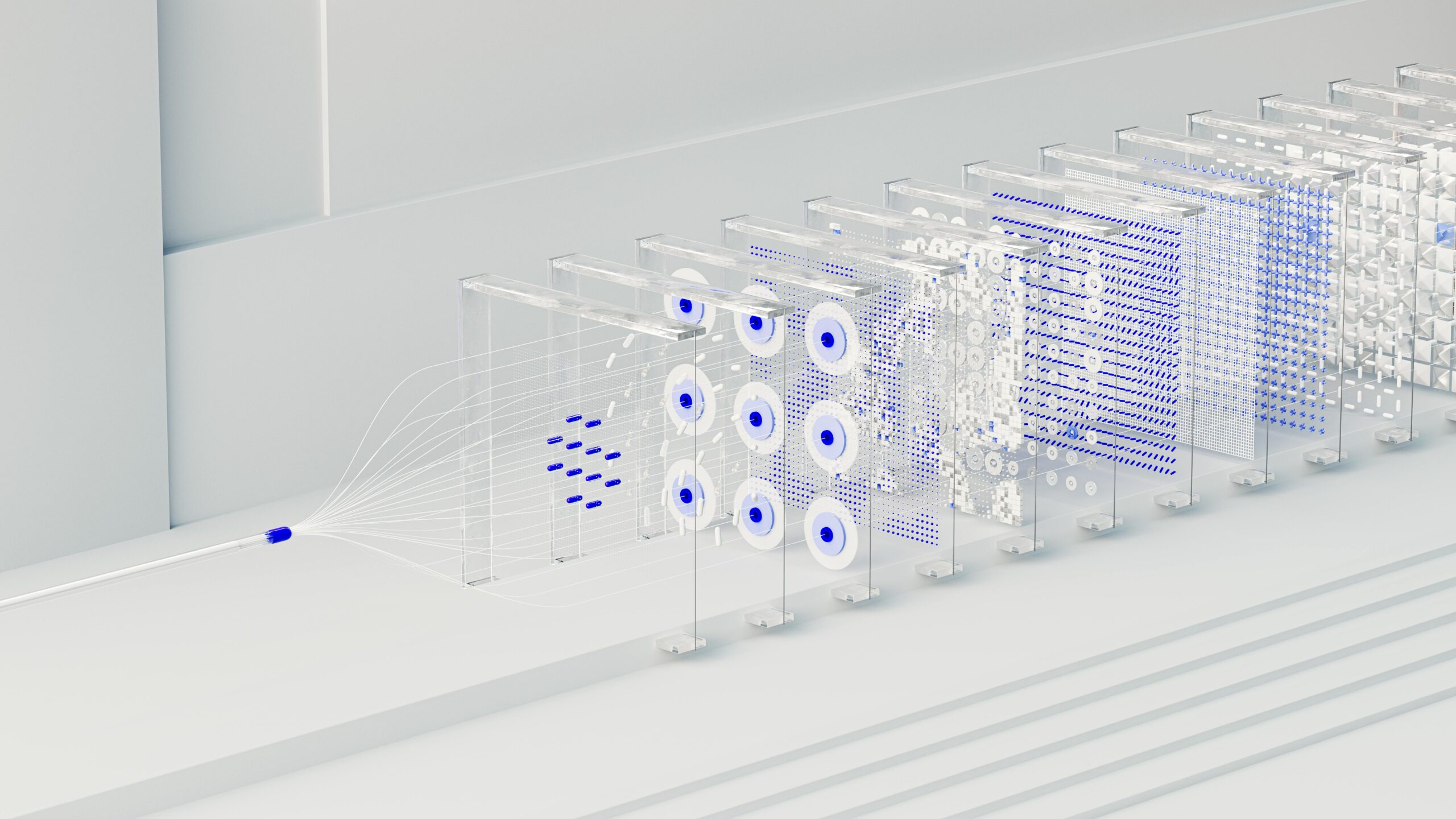

Sensor technology has revolutionized how we monitor and understand our world, from deep ocean trenches to Arctic research stations. However, the gap between laboratory conditions and real-world harsh environments represents one of the most significant challenges in modern sensing technology. Extreme temperatures, corrosive substances, intense vibrations, electromagnetic interference, and physical impacts can quickly render standard sensors useless.

The stakes are high across multiple industries. In oil and gas operations, sensor failure can mean millions in lost production or catastrophic safety incidents. Manufacturing plants rely on continuous monitoring to prevent equipment failures that could halt entire production lines. Environmental monitoring stations in remote locations must operate reliably for years without maintenance visits. Understanding what constitutes a “harsh environment” is the first step toward successful sensor deployment.

Defining Your Environmental Adversaries

Before selecting sensors, you must thoroughly characterize the hostile conditions they’ll face. Temperature extremes rank among the most common challenges, with some applications requiring operation from -60°C in polar regions to +200°C in industrial furnaces. But temperature alone rarely tells the full story.

Moisture and chemical exposure create corrosive environments that degrade electronic components and sensor housings. Dust and particulates can clog openings, interfere with optical sensors, and create abrasive conditions. Pressure variations from deep underwater installations to high-altitude applications stress sensor enclosures and affect calibration. Vibration and shock from heavy machinery or transportation applications can cause physical damage and drift in sensor readings.

Creating a Comprehensive Environmental Profile

Successful deployments begin with detailed environmental assessments. Document temperature ranges, including both sustained conditions and transient spikes. Measure humidity levels and identify potential condensation zones. Analyze chemical exposure risks, including pH levels, solvent presence, and corrosive gas concentrations. Assess mechanical stresses from vibration frequencies, shock events, and acoustic noise.

This environmental profile becomes your specification document, guiding every subsequent decision about sensor selection, housing design, and installation methodology. Underestimating any single factor can compromise an entire deployment, making this assessment phase critical to project success.

⚙️ Selecting Sensors Built for Survival

Not all sensors are created equal when facing environmental extremes. Industrial-grade sensors incorporate specific design features that distinguish them from consumer or laboratory equipment. Understanding these differences enables informed selection decisions that balance performance requirements against budget constraints.

Temperature-hardened sensors use specialized materials and construction techniques. Silicon-on-insulator technology provides better high-temperature performance than standard CMOS designs. Hermetically sealed packages protect internal components from moisture and contaminants. Some sensors incorporate internal temperature compensation circuits that maintain accuracy across wide temperature ranges.

Material Selection Makes the Difference

The materials used in sensor construction directly impact survival in harsh conditions. Stainless steel housings resist corrosion better than aluminum in marine environments. Titanium offers exceptional strength-to-weight ratios and chemical resistance for aerospace applications. Ceramic materials withstand extreme temperatures and provide excellent electrical insulation.

For sensing elements themselves, material choices depend on the measurement principle. Piezoelectric sensors using quartz crystals offer stability across temperature ranges. Capacitive sensors with ceramic dielectrics resist humidity effects. Optical sensors with sapphire windows withstand abrasion and high pressures. Understanding these material properties helps match sensors to specific environmental challenges.

Enclosure Engineering: Your First Line of Defense

Even the most robust sensor requires appropriate enclosure protection. Ingress Protection (IP) ratings provide a standardized measure of enclosure effectiveness against solid objects and liquids. An IP68 rating indicates complete dust protection and continuous immersion capability, while IP69K adds high-temperature, high-pressure washdown resistance.

However, IP ratings don’t capture every environmental threat. Custom enclosure design addresses application-specific challenges. Explosion-proof housings for hazardous locations meet strict standards preventing ignition of flammable atmospheres. Radiation-hardened enclosures shield sensors in nuclear facilities. Vibration-isolated mountings protect against mechanical stress in transportation applications.

Thermal Management Strategies

Temperature extremes demand active thermal management approaches. Heat sinks dissipate excess thermal energy in high-temperature environments. Thermoelectric coolers maintain stable sensor temperatures despite external variations. Insulation materials protect against both heat and cold, with aerogel insulators offering exceptional performance in minimal space.

Ventilation presents a paradox in enclosure design. Sensors measuring air quality or gas concentrations require environmental access, but openings compromise protection. Sintered metal filters allow gas exchange while blocking particles and liquids. Gore-Tex membranes equalize pressure changes while maintaining weatherproofing. Tortuous path designs let air circulate while preventing direct water ingress.

🔌 Power Systems That Won’t Quit

Reliable sensor operation requires reliable power, but harsh environments challenge conventional power supply approaches. Battery performance degrades at temperature extremes, with lithium batteries losing capacity below freezing and risking thermal runaway at high temperatures. Connection reliability suffers from thermal cycling, vibration, and corrosion.

Energy harvesting technologies offer solutions for remote deployments. Solar panels work well in sunny locations but require careful positioning and cleaning protocols in dusty environments. Thermoelectric generators convert temperature differentials into electrical power, useful in applications with waste heat. Vibration energy harvesters capture mechanical energy from machinery or structural movements.

Conditioning and Distribution Challenges

Power conditioning becomes critical in electrically noisy environments. Voltage transients from lightning, motor switching, or welding operations can destroy unprotected electronics. Surge protection devices, isolation transformers, and filtered power supplies provide defense layers. Redundant power paths ensure continued operation if one supply fails.

Wiring methods must match environmental severity. Armored cables resist physical damage and electromagnetic interference. Sealed connectors prevent moisture ingress at connection points. Cable glands and conduit entries require proper installation to maintain enclosure integrity. In the most extreme cases, wireless power transmission eliminates vulnerable wired connections entirely.

Data Communication in the Wild

Collecting data means nothing if you can’t retrieve it reliably. Wired communication offers reliability but requires physical connections vulnerable to environmental damage. Fiber optic cables resist electromagnetic interference and operate across long distances but require careful installation. Ethernet connections provide high bandwidth but need proper surge protection and sealing.

Wireless technologies eliminate physical connection vulnerabilities while introducing new challenges. Radio frequency propagation suffers in metal structures and underground installations. Long-range wireless protocols like LoRaWAN operate over kilometers but offer limited bandwidth. Cellular connections provide convenience but depend on network coverage and recurring fees. Satellite communications reach anywhere but involve higher costs and power requirements.

Edge Computing and Local Storage

Processing data locally reduces communication requirements and improves system resilience. Edge computing devices analyze sensor readings on-site, transmitting only relevant information or alerts. This approach conserves bandwidth, reduces power consumption, and maintains functionality during communication outages.

Local data storage provides backup when communication fails. Industrial SD cards rated for extended temperatures and write cycles offer removable storage. EEPROM and flash memory integrated into sensor modules protect critical calibration data. Redundant storage across multiple devices prevents single-point data loss.

🛠️ Installation Best Practices for Longevity

Perfect equipment poorly installed fails just as certainly as inadequate equipment. Installation methodology significantly impacts long-term reliability. Proper mounting prevents vibration damage and maintains sensor alignment. Torque specifications ensure adequate sealing without damaging threads or gaskets. Cable routing protects against abrasion, snagging, and stress at connection points.

Environmental sealing requires meticulous attention. Thread sealants must be compatible with process fluids and temperature ranges. O-rings need correct compression ratios and compatible materials. Gasket surfaces must be clean and undamaged. Any compromise in sealing integrity allows environmental ingress that can cascade into complete system failure.

Testing and Validation Before Deployment

Pre-deployment testing identifies problems while fixes remain easy and inexpensive. Pressure testing verifies enclosure integrity before installation in hazardous locations. Temperature cycling reveals thermal expansion issues and connection reliability. Vibration testing simulates operational conditions. Communication range testing confirms wireless connectivity in actual deployment locations.

Documentation during installation proves invaluable for future maintenance and troubleshooting. Photograph installation details, especially connection configurations and routing paths. Record calibration values and baseline readings. Note any installation deviations from original plans. This documentation accelerates problem diagnosis when issues inevitably arise.

Maintenance Strategies for Sustained Performance

Harsh environment sensors require proactive maintenance approaches. Scheduled inspections catch problems before they cause failures. Cleaning protocols remove accumulated contaminants that affect sensor performance. Calibration verification ensures continued accuracy. Component replacement addresses wear items before they fail.

Condition-based maintenance uses sensor data to optimize maintenance timing. Tracking measurement drift identifies sensors needing recalibration. Monitoring communication signal strength predicts connectivity issues. Analyzing power consumption reveals developing electrical problems. This approach focuses resources on equipment actually needing attention rather than arbitrary schedules.

Remote Monitoring and Diagnostics

Modern sensor systems incorporate self-diagnostic capabilities enabling remote health monitoring. Built-in test circuits verify sensor functionality. Communication systems report signal strength and error rates. Power monitoring tracks supply voltages and currents. These diagnostics enable proactive intervention before complete failures occur.

Remote configuration capabilities reduce maintenance visit requirements. Firmware updates correct bugs and add features without physical access. Calibration adjustments compensate for drift. Communication parameter changes optimize performance for varying conditions. These capabilities dramatically reduce total ownership costs for remote installations.

📊 Real-World Success Stories

Learning from successful deployments provides valuable insights. Arctic research stations maintain continuous environmental monitoring through brutal winters by combining proper enclosure design with energy-efficient heating systems. The sensors operate reliably at -50°C because designers specified components rated for these extremes and implemented preemptive thermal management.

Offshore oil platforms deploy thousands of sensors in corrosive marine environments exposed to salt spray, humidity, and temperature swings. Success comes from using marine-grade stainless steel housings, gold-plated connections, and silicone conformal coatings on circuit boards. Regular inspection and preventive replacement programs maintain reliability despite harsh conditions.

Steel mills monitor temperatures exceeding 1000°C using water-cooled sensor housings and ceramic sensing elements. The installations survive because of proper thermal barriers, continuous cooling flow verification, and redundant sensor deployment. When individual sensors fail, parallel units maintain process visibility until replacement during scheduled maintenance windows.

Cost-Benefit Analysis: Investing in Durability

Industrial-grade sensors cost significantly more than standard alternatives, sometimes ten times or more. This price difference causes sticker shock during procurement, but total ownership cost analysis reveals the true value proposition. A consumer-grade sensor costing $50 that fails monthly generates replacement costs, downtime losses, and labor expenses far exceeding a $500 industrial sensor operating reliably for years.

Calculating total cost requires considering multiple factors. Sensor purchase price represents only the starting point. Installation labor, especially in difficult locations, often exceeds equipment costs. Downtime during sensor failures creates production losses and missed data collection. Maintenance visit costs for remote locations can be enormous. Extended warranties and vendor support agreements provide insurance against unexpected expenses.

🚀 Emerging Technologies and Future Trends

Sensor technology continues advancing, with innovations specifically targeting harsh environment challenges. MEMS sensors fabricated from silicon carbide operate reliably above 300°C. Wireless sensor networks with mesh topologies provide redundant communication paths. Energy harvesting improvements enable truly maintenance-free deployments. Machine learning algorithms detect anomalies and predict failures based on sensor data patterns.

Nanotechnology promises revolutionary improvements in sensor durability and performance. Nanocoatings provide superior corrosion resistance with minimal thickness. Carbon nanotube sensors withstand extreme temperatures while offering exceptional sensitivity. Self-healing materials automatically repair minor damage, extending sensor lifetimes.

Digital twin technology creates virtual models of sensor systems, enabling simulation of failure scenarios and optimization of maintenance strategies. These models incorporate real-world sensor data, continuously improving their accuracy and predictive capabilities. The approach reduces costly physical testing while improving system reliability.

Building Your Deployment Strategy

Successfully deploying sensors in harsh environments requires systematic planning and execution. Start with thorough environmental characterization, documenting every threat sensors will face. Select equipment specifically rated for your conditions, resisting temptation to economize on critical components. Design comprehensive protection through appropriate enclosures, mounting systems, and installation practices.

Implement robust power and communication systems with appropriate redundancy. Establish maintenance programs balancing proactive intervention against resource constraints. Leverage remote monitoring capabilities to maximize uptime and optimize maintenance timing. Document everything, creating knowledge bases that improve with each deployment.

Partner with experienced vendors who understand harsh environment applications. Their expertise often proves more valuable than equipment costs alone. Request reference installations in similar conditions. Involve them early in planning stages when their input provides maximum value. Establish clear support agreements covering response times, spare parts availability, and technical assistance.

Harsh environment sensor deployments represent significant investments demanding careful planning and execution. However, the rewards of reliable data collection in extreme conditions justify these efforts. Whether monitoring critical infrastructure, enabling scientific research, or optimizing industrial processes, properly deployed sensors provide visibility and control that would otherwise be impossible. By understanding environmental challenges, selecting appropriate equipment, implementing robust installation practices, and maintaining proactive support, you can achieve successful sensor deployments that survive and thrive in the harshest conditions our world presents.

Toni Santos is a bioacoustic researcher and conservation technologist specializing in the study of animal communication systems, acoustic monitoring infrastructures, and the sonic landscapes embedded in natural ecosystems. Through an interdisciplinary and sensor-focused lens, Toni investigates how wildlife encodes behavior, territory, and survival into the acoustic world — across species, habitats, and conservation challenges. His work is grounded in a fascination with animals not only as lifeforms, but as carriers of acoustic meaning. From endangered vocalizations to soundscape ecology and bioacoustic signal patterns, Toni uncovers the technological and analytical tools through which researchers preserve their understanding of the acoustic unknown. With a background in applied bioacoustics and conservation monitoring, Toni blends signal analysis with field-based research to reveal how sounds are used to track presence, monitor populations, and decode ecological knowledge. As the creative mind behind Nuvtrox, Toni curates indexed communication datasets, sensor-based monitoring studies, and acoustic interpretations that revive the deep ecological ties between fauna, soundscapes, and conservation science. His work is a tribute to: The archived vocal diversity of Animal Communication Indexing The tracked movements of Applied Bioacoustics Tracking The ecological richness of Conservation Soundscapes The layered detection networks of Sensor-based Monitoring Whether you're a bioacoustic analyst, conservation researcher, or curious explorer of acoustic ecology, Toni invites you to explore the hidden signals of wildlife communication — one call, one sensor, one soundscape at a time.