Monitoring systems are the backbone of modern operations, but without proper maintenance protocols, even the best technology falls short of delivering lasting value and actionable insights.

🎯 Why Maintenance Protocols Define Monitoring Success

Long-term monitoring success isn’t achieved through advanced technology alone. The difference between systems that deliver consistent value and those that become costly burdens lies in how organizations approach maintenance. Systematic protocols ensure that monitoring infrastructure remains reliable, accurate, and aligned with evolving business needs.

Organizations investing in monitoring solutions often overlook the operational discipline required to sustain performance over time. Equipment degrades, software requires updates, calibration drifts occur, and data integrity issues emerge gradually. Without structured maintenance protocols, these incremental problems compound into significant failures that compromise decision-making capabilities.

The cost of monitoring system failures extends beyond immediate technical issues. Inaccurate data leads to flawed decisions, compliance violations trigger regulatory penalties, and system downtime creates operational blind spots. Establishing robust maintenance protocols transforms monitoring from a reactive expense into a proactive asset that consistently delivers ROI.

📋 Building Your Foundation: Essential Documentation Practices

Effective maintenance begins with comprehensive documentation. Creating detailed records of your monitoring infrastructure establishes the foundation for systematic upkeep and continuous improvement. Documentation should capture equipment specifications, installation parameters, calibration histories, maintenance schedules, and performance baselines.

Digital asset management systems provide centralized repositories where teams can access critical information instantly. When technicians understand equipment history and operational context, they diagnose issues faster and implement solutions more effectively. Documentation also facilitates knowledge transfer, preventing organizational vulnerability when personnel changes occur.

Critical Documentation Components

Your maintenance documentation framework should include several key elements that support both routine operations and troubleshooting scenarios:

- Equipment inventories with unique identifiers, purchase dates, warranty information, and vendor contacts

- Configuration baselines documenting initial setup parameters and subsequent modifications

- Calibration certificates tracking accuracy verification and adjustment history

- Maintenance logs recording all service activities, findings, and corrective actions

- Performance metrics establishing normal operating ranges and deviation thresholds

- Incident reports detailing failures, root causes, and resolution strategies

⚙️ Preventive Maintenance: The Cornerstone Strategy

Preventive maintenance represents the most cost-effective approach to long-term monitoring success. By performing scheduled inspections and service activities before failures occur, organizations avoid costly emergency repairs, minimize downtime, and extend equipment lifespan significantly.

Developing a preventive maintenance schedule requires understanding manufacturer recommendations, operational intensity, environmental conditions, and historical performance patterns. High-use equipment in harsh environments demands more frequent attention than sensors in controlled settings with moderate utilization.

Optimizing Your Preventive Maintenance Schedule

Effective scheduling balances thoroughness with operational efficiency. Overly aggressive maintenance wastes resources and creates unnecessary disruption, while insufficient attention allows problems to develop undetected. The optimal approach considers multiple factors:

Equipment criticality determines maintenance priority. Systems supporting safety-critical functions, regulatory compliance, or high-value operations require more rigorous protocols than redundant or non-essential monitoring points. Risk-based prioritization ensures resources focus where they generate maximum protective value.

Manufacturer guidelines provide baseline recommendations, but operational reality may necessitate adjustments. Equipment operating beyond design parameters or in suboptimal conditions typically requires enhanced maintenance frequency. Conversely, systems in favorable conditions with light utilization may safely extend intervals.

Historical performance data reveals actual maintenance needs. Tracking failure patterns, degradation rates, and service findings identifies where adjustments improve outcomes. This evidence-based approach continuously refines schedules based on real-world experience rather than theoretical assumptions.

🔍 Calibration Management: Ensuring Data Integrity

Calibration maintains the accuracy that makes monitoring data actionable. Sensors and instruments drift over time due to wear, environmental exposure, and inherent component characteristics. Regular calibration verifies measurement accuracy and corrects deviations before they compromise data quality.

Calibration protocols should define frequency, methodology, acceptance criteria, and documentation requirements. Regulatory environments often mandate specific calibration standards, creating non-negotiable compliance obligations. Even absent external requirements, internal quality standards should enforce rigorous calibration discipline.

Implementing Robust Calibration Procedures

Effective calibration management requires standardized processes that ensure consistency across all monitoring points. Procedures should specify reference standards, environmental conditions, acceptance tolerances, and adjustment protocols. Technicians need clear guidance that eliminates ambiguity and variation in execution.

Calibration frequency depends on measurement criticality, accuracy requirements, stability characteristics, and regulatory mandates. Critical measurements supporting safety decisions or compliance obligations demand more frequent verification than informational monitoring. High-precision applications require tighter intervals than systems tolerating broader accuracy ranges.

Documentation transforms calibration from a technical activity into quality evidence. Detailed records demonstrate compliance, support audit requirements, and provide performance trends indicating when equipment requires replacement. Calibration certificates should capture as-found conditions, adjustments performed, as-left status, and technician identification.

💻 Software and Firmware: The Digital Maintenance Dimension

Modern monitoring systems rely heavily on software and firmware that require ongoing maintenance. Updates address security vulnerabilities, fix bugs, add features, and improve performance. Neglecting digital maintenance exposes systems to cyber threats, operational glitches, and compatibility issues.

Update management requires balancing currency with stability. Immediately installing every update risks introducing untested changes that disrupt operations. Conversely, deferring updates indefinitely accumulates technical debt and security exposure. Strategic update policies define appropriate timing based on criticality, testing requirements, and vendor recommendations.

Developing Your Software Maintenance Strategy

Effective software maintenance begins with inventory management. Comprehensive catalogs identifying all software components, versions, licensing status, and vendor support relationships enable informed decision-making. Without complete visibility, systems languish on unsupported versions that become security liabilities and operational risks.

Testing protocols validate updates before production deployment. Sandbox environments allow teams to verify functionality, identify conflicts, and develop rollback procedures before exposing operational systems to change. Critical monitoring infrastructure should never serve as testing grounds for unvetted software modifications.

Change management processes coordinate updates across integrated systems. Monitoring ecosystems often include multiple interconnected components where version compatibility determines operational success. Systematic change management prevents situations where updating one element breaks dependencies and creates cascading failures.

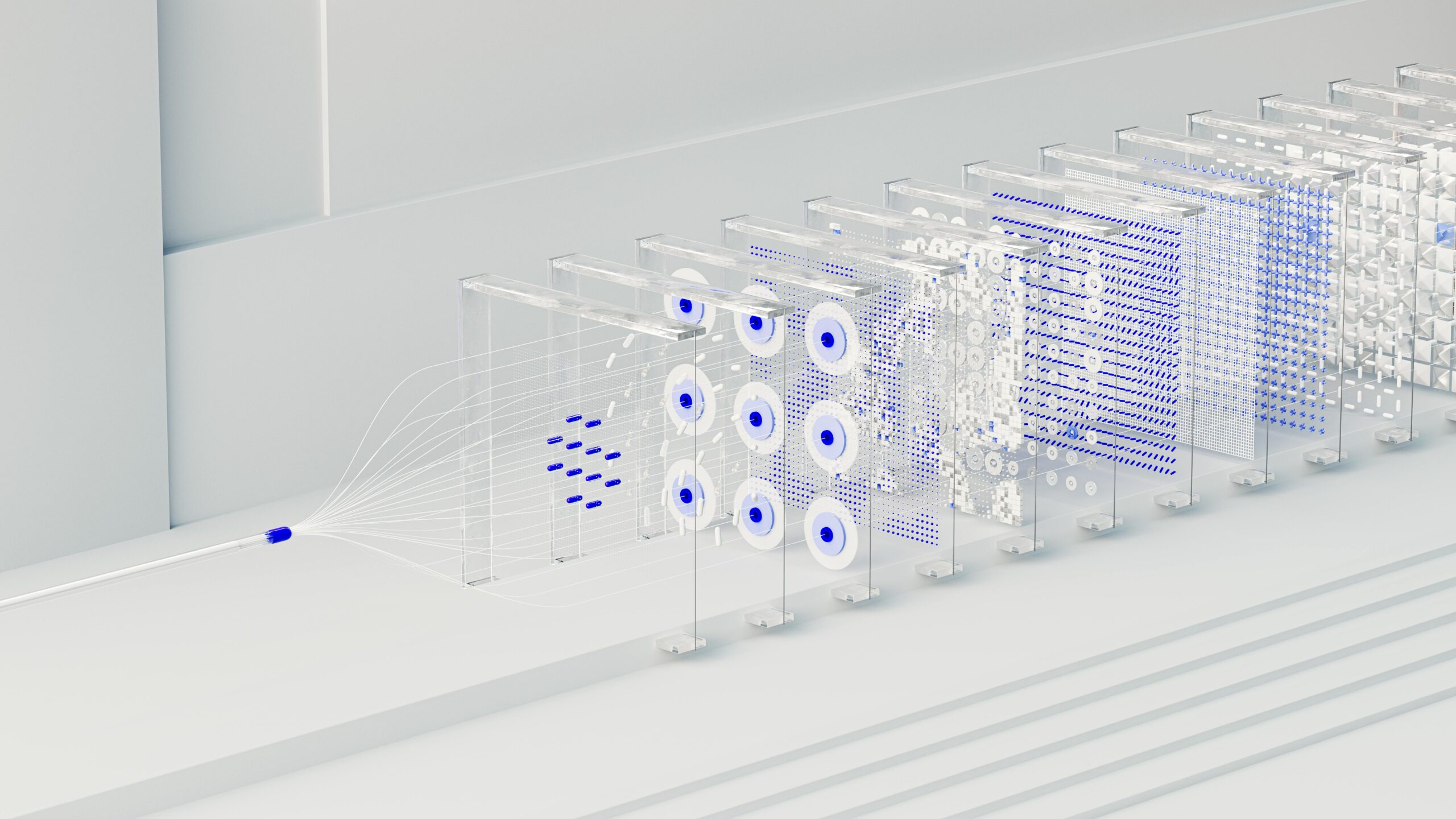

🛠️ Predictive Maintenance: Leveraging Advanced Analytics

Predictive maintenance represents the evolution beyond scheduled preventive approaches. By analyzing performance trends, operational patterns, and condition indicators, organizations identify impending failures before they occur. This intelligence enables targeted interventions that prevent disruptions while optimizing maintenance resource allocation.

Implementing predictive maintenance requires collecting and analyzing appropriate condition indicators. Vibration signatures, temperature profiles, power consumption patterns, and performance metrics provide insights into equipment health. Machine learning algorithms identify subtle patterns indicating degradation that human observation might miss.

Building Predictive Capabilities

Predictive maintenance success depends on data quality and analytical sophistication. Sensors must capture relevant condition indicators with sufficient frequency and precision to detect meaningful changes. Baseline establishment requires extended observation periods documenting normal operation across various conditions.

Analytical models translate raw data into actionable intelligence. Statistical algorithms flag deviations from established norms, while trend analysis projects failure timelines. These insights enable maintenance scheduling that addresses problems during planned windows rather than emergency responses to unexpected failures.

Integration with maintenance workflows ensures predictions drive action. Alerts should automatically generate work orders, notify appropriate personnel, and trigger procurement of necessary parts. Connecting prediction to execution closes the loop that transforms insights into outcomes.

📊 Performance Monitoring: Measuring Maintenance Effectiveness

Systematic measurement determines whether maintenance protocols deliver intended value. Key performance indicators track system reliability, data quality, maintenance costs, and operational availability. These metrics reveal protocol effectiveness and identify improvement opportunities.

Mean time between failures quantifies reliability improvements resulting from maintenance investments. Tracking this metric over time demonstrates whether protocols successfully reduce failure frequency. Segmenting data by equipment type, location, or operational context identifies where efforts generate greatest impact.

Essential Maintenance Metrics

Comprehensive performance measurement encompasses multiple dimensions reflecting different success factors:

| Metric Category | Key Indicators | Strategic Value |

|---|---|---|

| Reliability | MTBF, system availability, failure rate | Measures operational dependability |

| Data Quality | Accuracy deviation, calibration compliance | Validates monitoring integrity |

| Cost Efficiency | Maintenance cost per asset, emergency vs. planned ratio | Demonstrates financial optimization |

| Responsiveness | Mean time to repair, work order completion rate | Reflects maintenance capability |

👥 Training and Knowledge Development

Technical competence determines maintenance quality regardless of protocol sophistication. Investing in personnel training ensures teams possess skills and knowledge required to execute maintenance effectively. Comprehensive training programs address equipment operation, troubleshooting methodologies, safety procedures, and documentation requirements.

Ongoing education maintains competence as technology evolves and protocols improve. Regular refresher training reinforces proper techniques, while advanced courses develop specialized capabilities. Cross-training builds organizational resilience by reducing dependence on individual expertise.

Building Maintenance Excellence

Effective training extends beyond initial onboarding to create continuous learning cultures. Mentorship programs pair experienced technicians with newer team members, facilitating knowledge transfer that preserves institutional expertise. Regular competency assessments identify skill gaps requiring targeted development interventions.

Documentation serves as permanent knowledge repositories supplementing human expertise. Well-written procedures, troubleshooting guides, and reference materials enable technicians to perform complex tasks consistently. Video demonstrations and annotated photographs enhance understanding beyond text-based instructions.

🔐 Security Considerations in Maintenance Operations

Maintenance activities create potential security vulnerabilities requiring careful management. Physical access to monitoring equipment provides opportunities for tampering or unauthorized modifications. Remote connectivity enabling software updates and configuration changes introduces cyber security considerations.

Access control protocols ensure only authorized personnel perform maintenance activities. Authentication mechanisms verify identity, while authorization systems enforce role-based permissions. Comprehensive audit trails document who accessed what systems when, creating accountability and supporting forensic investigations if incidents occur.

Change management procedures prevent unauthorized modifications that compromise security or functionality. Formal approval processes require justification and authorization before implementing changes. Version control systems track modifications, enabling rollback if problems emerge.

🌐 Remote Monitoring and Maintenance Capabilities

Remote capabilities extend maintenance reach while reducing costs associated with physical site visits. Network connectivity enables technicians to access systems from anywhere, performing diagnostics, adjusting configurations, and updating software without travel expenses or delays.

Remote maintenance requires robust security architectures protecting against unauthorized access. Encrypted connections, multi-factor authentication, and network segmentation prevent cyber threats from exploiting remote access channels. Regular security assessments identify vulnerabilities requiring remediation.

Maximizing Remote Maintenance Value

Effective remote maintenance balances convenience with operational constraints. Some activities inherently require physical presence—sensor cleaning, component replacement, or hands-on troubleshooting cannot occur remotely. Optimal strategies leverage remote capabilities where appropriate while efficiently scheduling necessary site visits.

Remote monitoring data informs maintenance planning by revealing conditions requiring intervention. Real-time alerts notify teams immediately when parameters exceed thresholds, enabling rapid response before minor issues escalate. Historical trending identifies gradual degradation patterns that schedule preventive maintenance proactively.

♻️ Sustainable Maintenance Practices for Lasting Success

Long-term monitoring success requires sustainable practices that balance performance, cost, and environmental responsibility. Equipment lifecycle management considers total ownership costs including acquisition, operation, maintenance, and disposal. Selecting reliable, maintainable technology reduces lifetime expenses despite potentially higher initial investments.

Environmental considerations increasingly influence maintenance decisions. Energy-efficient equipment reduces operational costs while minimizing carbon footprints. Proper disposal of obsolete equipment, batteries, and hazardous materials demonstrates environmental stewardship and regulatory compliance.

Continuous improvement cultures drive ongoing protocol refinement. Regular reviews assess what’s working well and where adjustments improve outcomes. Feedback loops connecting maintenance personnel with system users identify pain points and opportunities that formal metrics might miss.

🚀 Transforming Maintenance Into Strategic Advantage

Organizations that excel at maintenance protocols transform operational necessity into competitive advantage. Reliable monitoring systems enable better decisions, faster responses, and superior outcomes compared to competitors struggling with unreliable data and frequent failures.

Strategic maintenance planning aligns protocols with organizational objectives. Understanding how monitoring supports business goals ensures maintenance priorities reflect actual value contribution. This alignment secures necessary resources and organizational commitment for maintenance excellence.

Maintenance protocols represent living frameworks requiring adaptation as technology, requirements, and understanding evolve. What works today may need modification tomorrow as conditions change. Flexibility combined with disciplined execution creates sustainable monitoring success that delivers value year after year, maximizing your investment while minimizing operational disruptions.

Toni Santos is a bioacoustic researcher and conservation technologist specializing in the study of animal communication systems, acoustic monitoring infrastructures, and the sonic landscapes embedded in natural ecosystems. Through an interdisciplinary and sensor-focused lens, Toni investigates how wildlife encodes behavior, territory, and survival into the acoustic world — across species, habitats, and conservation challenges. His work is grounded in a fascination with animals not only as lifeforms, but as carriers of acoustic meaning. From endangered vocalizations to soundscape ecology and bioacoustic signal patterns, Toni uncovers the technological and analytical tools through which researchers preserve their understanding of the acoustic unknown. With a background in applied bioacoustics and conservation monitoring, Toni blends signal analysis with field-based research to reveal how sounds are used to track presence, monitor populations, and decode ecological knowledge. As the creative mind behind Nuvtrox, Toni curates indexed communication datasets, sensor-based monitoring studies, and acoustic interpretations that revive the deep ecological ties between fauna, soundscapes, and conservation science. His work is a tribute to: The archived vocal diversity of Animal Communication Indexing The tracked movements of Applied Bioacoustics Tracking The ecological richness of Conservation Soundscapes The layered detection networks of Sensor-based Monitoring Whether you're a bioacoustic analyst, conservation researcher, or curious explorer of acoustic ecology, Toni invites you to explore the hidden signals of wildlife communication — one call, one sensor, one soundscape at a time.